Archive for July 2016

It is two years since I asked Dudley Dix to redesign the cockpit to my liking and I am delighted with the result

With the underside of the cockpit coamings painted white and the last of the deck covered in epoxy glass I woke early to put the coamings back on the deck and take a photo. I still have to glue and screw the coamings in place but I am happy with the final shape.

All the deck is not glassed with the exception of the transom. The sugar scoop stern is completed and glassed but there is still the locker lid and hatch surrounds to do. The photo shows the tiny beads of epoxy bog filleted into the corners to ensure that there are no air bubbles in the epoxy glass coating

A first last week did not do too much damage to the handicap as the result was close. The second place today will do more damage as we were well in front of the fleet on handicap with the exception of Rainbow. Rainbow had a few bad races and her handicap quickly improved but her big win today will see her come back to the pack.

The No 3 tacked to the deck and a single reef in the main worked a treat today. On the run to South Head we stayed close to the fleet and even rounded in front of Krakatoa in what must be a first for Passion. The work back to Rose Bay was not too tight so we could keep speed up and hit 7.7 knots. The whole fleet was moving similarly but relative to our usual speed we were doing better. We powered over Izzi and took time out of Rainbow. On the work from Rose Bay to Shark Island we almost called on the the Bethwaites for afternoon tea but eventually the covering yacht tacked and we were able to go over on to port tack well ahead of the yacht that had tacked to port earlier. Here we passed Rainbow and drew further in front of Izzi. We went wide of the lee of the island on the way around and made up a bit of ground on Larrikin and Brittania. It was enough ground for us to catch Britannia on the work to the finish despite their very best endeavours to pinch up into our path.

In the end the handicap Rainbow had was too much for us and we had to settle for second place but an increased lead in the progressive total.

Like the cattle herd that stampedes towards the water hole I can smell the water and am pushing hard to get the yacht completed. I wanted to see what the stern would look like once finished so I pushed hard to get a photo opportunity late today. Ron gave me a hand on Friday to glue the panels he had cut into place. I had planned to leave the glue to cure for a couple of days but Friday was so warm and warm so late in the night that the glue was rock solid by Saturday morning. That gave me the chance to glue on the capping pieces and let them cure over Saturday night. By late afternoon the glue was cured enough for me to trim the excess and take the photo as the sun was going down. The reinforcement for the winch based under the cockpit coamings is also completed so tomorrow after a final sand I will coat the insides with epoxy primer. On the exterior the woodworking jobs to go are the mast step base, two cabin hatch surrounds and the detail around the companionway, the locker lid and the gas bottle compartment lid. These are not too complicated so we shall see how we progress this week. There are still toe rails to do so perhaps I should make up my mind what timber to us and order it. I have started to buy fittings so that we can drill the holes and locate the areas that need reinforcement. I want to add any under deck reinforcement before I paint the underside of the deck.

The coamings now have the four fibreglass winch bases cut in and bogged in place ready for the final glass reinforcement. The first job today was to trim the excess glass from the last two winch bases and vacuum up the fibreglass dust. I took the port coamings to the garage to cut the holes for the winch bases. Before fitting the bases I trimmed the excess plywood from the joins and vacuumed up the wood dust. Because I could turn the coamings around I found it easier to power plane the excess plywood in the garage than it would have been if they had been glued to the deck. Once the port coamings were ready to fit the winch bases I retrieved the starboard coamings from the hull and finished the fairing on those. I reused the temporary supports from under the starboard coamings on the port side and there is a photo to show how they fit. Several vacuum cleans of the garage later the winch bases were ready to bog in place. Even with winter hardener the epoxy filleting around the bases was going to take all afternoon to cure and I had other jobs to do. I have been putting off finishing the sugar scoop stern because it is a fiddly job and there is not much progress to show. However with mates coming tomorrow to help fit the inside liners there was a deadline to meet to glue all the pieces into place. The task was neither as difficult or as time consuming as I had anticipated and in a short afternoon they are all glued in place. I have used the final capping plywood as a gluing guide for the infill pieces. By temporarily screwing the capping plywood in place and by protecting it with kitchen paper I was able to clamp each of the pieces to the plywood capping piece. Tomorrow when the glue has cured it should be a quick tidy up before fitting the inside liner of the sugar scoop stern. As a bonus the capping pieces are ready to go and the wood dust is vacuumed up too.

Daybreak on Wednesday was a miserable wet one. Rain was blowing in under the awning so it was best to leave the tarpaulins on the Didi 40 CR and do some shopping pre the Winter Wednesday race at RANSA. In the miserable conditions I can understand crews opting for the comfort of a fireplace and a good book but nine hardy regular crews took to the water in Division 1.

The leg out to South Head was a tricky run sometimes square and sometimes on the beam. I chased the wind directions around the course trying to keep the poled out genoa setting. One of our crew had the day off and took some photos of us battling it out with club mate Izzi on the run. Our tactics must have worked because we arrived at the mark mid fleet and looking good on handicap. On the work back to Rose Bay I could not find the groove with the No 1 headsail. The entry was too flat for the telltales to stream on both sides of the sail so I asked Kevin to helm while I fiddled with settings. A bit more luff tension and moving the genoa cars forward a notch helped to get Passion moving. At the bow looking up at the flow in the big black No 1 heavy genoa it is obvious that the sail needs some forestay sag to get the shape in the luff. The main however needs some mast bend to free the leech so the combination works better with a bit of breeze. Now that we had settled into a groove we were holding Aggrovation and Izzi to windward. We swapped tacks a couple of times with Aggrovation and managed to be above them on starboard approaching what was to be the last turning mark on a shortened course. The last run to the finish was a poled out affair and we were lucky to get a clear run to the finish while Aggrovation was blanketed from behind. That let Izzi charge through to the finish. It was good to be so close to our club mates and even better to just pip them at the finish. With our more benevolent handicap we won the day and increased our lead on the progressive pointscore. This was our reward for braving the rain.

After a pleasant break visiting family on the north coast it was back to the cockpit coamings on Saturday and Monday. On Saturday I finished the third coat of varnish on the bunk tops and they are stored away for now.

In the coamings there are pockets for storage and also for access to the underside of the winch pads. I marked and cut these and then glued up the starboard coamings. Time was getting away so Elaine held the work light up for me as I finished gluing and screwing the panels together. Sunday is a church day but our prayers for wind for the afternoon winter race were unanswered. It was however a nice warm sunny day and the complimentary BBQ back on the deck at Greenwich Flying Squadron made it one of the best afternoon of the winter.

Today I laminated up the first winch base in a bucket and while it was curing removed the starboard coamings from the deck. To my relief they came away easily and the underside is very tidy and ready for glassing. Next task was to glue up the port side coamings making sure that there was enough kitchen paper under the cleats so that any surplus glue did not stick it to the deck. By this time the first winch base had cured in the warm sunny position I had placed it so I could remove it from the mould and start the second one. I had visions of doing a third winch base in a second mould but time, light and energy deserted me so best to leave it for the morning. With luck I can do the two in the morning and still have them cured by the afternoon. The plan is to cut out an oval section of the plywood on the coamings and insert the winch bases into the hole and laminate the base to the coaming from below. Eight layers of 450 gram glass will give 4 mm of cured laminate equivalent in strength to 12 mm plywood. By the time the base is glassed in it will have 16 layers around join. The winch base will have a 12 mm plywood backing piece bogged in and glassed over. Hopefully the forecast rain will not stop any of this activity. The location of the winches proved a bit of a mystery. Dudley had three versions of the deck for the Didi 38, the extended Didi 40 with the long racing cockpit and the Didi 40 Cr with the shorter cockpit and longer cabin. Each version has a different winch base position. Our version has slightly shorter coamings because they finish where the cockpit widens out. By luck or good design our winches seem happiest located right in the middle of the coaming pockets. At 700 mm from the cabin and 700 mm spacing we have excellent access to the bolts under the bases and it looks very symmetrical. Our rear winches will double as running back stay and occasional spinnaker sheet winches so being located a bit further aft is appropriate. It is very much in the fashion of the more modern cruisers where one winch is in easy reach of the helm position. With our wide cockpit the coamings are 125 mm further outboard and they line up very well with the genoa cars so I might see how we go without cheek blocks on the coamings.

It was not quite a rerun of last week as the breeze was a couple of knots stronger and the chill factor a few degrees worse. As the breeze gusted up the lane Cover River straight into the doors of the club I was anxious about taking the tender out to Passion on the mooring. The crew from Aggrovation arrived having decided that Aggrovation was too exposed to the wind to board. They kept a watch on me as I rowed out to Passion and all was well close into the Greenwich hill.

On the water we did tack the No 3 genoa down to the deck and we did start with a reef in the main. On the run down the genoa was often blanketed by the main and often it was too tight to have the genoa poled out. Eventually we worked to windward enough to set the pole and from then kept in contact with the fleet. We did hit 8.9 knots in one spell which is a recent record and probably more reliable than just the speed through the water reading.

Immediately we turned the mark for the beat home we put in the second reef. I could see from the speed over the ground that we were going faster than last week with the two reefs in so I will concede that we would have been faster last week with one reef in. All around us our competitors with single reefs were having trouble while Izzi with a double reef was doing similarly well to ourselves.

Upwind the boat speed was at least a knot faster than last week. With the smaller main I could maintain shape in the genoa. L’Eau Co was alongside us again and this time we pulled away on the work for all of the race and not just the last dash to the finish. Izzi had run to the top mark faster but we were pulling her back ever so slowly on the beat home.

Around Shark Island we hit 8.3 knots with the double reefed main and I did promise the crew we would go at least three knots faster in the new Passion X in those conditions. I know the prototype did hit 17 knots with poled out genoa down a wave so I think I am on safe grounds with the speed promise.

Passion did hit 7 knots to windward at height similar to the other cruiser racers in the fleet and I confess I am less confident about the upwind speed of Passion X. We will have 13% more righting moment on a boat that is 25% lighter and 10% longer so I will be disappointed if we cannot be half a knot faster to windward.

On the work to the finish we passed Larrikin and drew further away from L’Eau Co but did not quite catch Izzi. Amante and The Biz took the major places while we scored a very safe third. If we can sail as well every windy day I will be very pleased.

We increased our lead in the series by a couple of points but a few behind us have 25 point races to drop which will bring them closer.

A bonus photo of progress on Passion X is included. It was so windy I had to take down the tarpaulin covering the stern and so could get a better picture of the coaming around the cockpit.

Now that most of the deck is protected from the wet by the epoxy glass coating I have started on the cockpit coamings. Coamings are a raised border around the cockpit to keep out the water. They also act as a back rest when sitting in the cockpit and sometimes can act as a seat when sitting outboard when the boat is heeled. It has taken two days to cut all the odd shaped longitudinal stringers and cleats as well as the odd shaped panels of plywood that form the coamings. They are all screwed into place temporarily. I propose to glue all the parts together but not to the deck so that I can remove the formed up coamings and turn them upside down to glass inside. That way I can incorporate the winch mounts as hollow structures glassed into the coamings as you would expect to find on a production yacht. i have a couple of plastic buckets ready to laminate up the winch bases and I might cut up one bucket and put it on the coamings just to see if it looks right.

We had just enough fine weather and just enough fibreglass cloth to complete most of the glassing of the deck of our Didi 40 Cr before the rain really set in. Thursday and Friday have been awful boat building days but with Kevin’s help we fitted the two chainplates on the side decks and the two plates for the running backstays. Late on Thursday I spent two hours hand sanding the roof beams in the cabin. Today was even more inclement and a meeting of the Sydney Harbour Users Group was a welcome break from the dust. This afternoon I donned sanding gear and spent half a day machine and hand sanding the roof in the V berth.

While I dislike the wet and cold there is much to do inside and once kitted up for the sanding it was quite comfortable lying in the V berth and looking up at the ceiling. A 100 mm foam mattress would have made it so much more comfortable.

Not wanting to leave too many tasks to the last minute I have lashed out and put a deposit on a new fat head mainsail. I had thought to get on the water with a modified pin head main off Passion and see how it went but as time has marched on all the trialing time has gone and we will need the new main at launch. In building the new yacht I made was determined not to go too high tech or add more expensive equipment than you would find on the average stock production yacht. What we have on Passion is the benchmark for what we will have on Passion X. That means the mainsail will be a radial cut from woven cloth. I am very keen on carbon for the genoas as the low stretch keeps the flow in the right position. With the mainsail supported on the mast I am less concerned for stretch and more concerned for reliability. I have gone for the Hydra Net Radial cloth as the lightest woven that will be suitable for the very low displacement of the Didi 40 Cr. I hope it is the right decision.

I have also put down a small deposit on the rig so that they can proceed with production drawings ahead of the full deposit that needs to be paid eight weeks before launch.

Inside we can measure up all the cushions and get these under way.

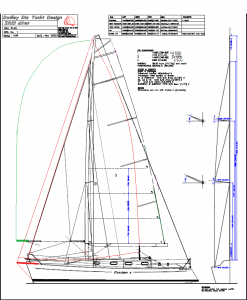

As a reminder of what the rig should look like I have included a sketch.

On Wednesday we enjoyed a fresh and gusty breeze with regular readings on the mast head of over 20 knots. In the conditions we set the No 3 genoa which is a 105% sail and the full main. Our competitors set a wide range of sail combinations. Allegro had the same arrangement as we did, Rainbow had a larger genoa and a reefed main while L’eau Co had a small no 4 and a full main. Only ten starters braved the weather so you could say the rest set no sail and pre start even under bare poles we had quite a lean in the gusts.

We were blown out to South Head at a fast clip with most yachts up to hull speed so the fleet was closely bunched at the turn mark. We were last around the mark but that is to be expected as the larger yachts had higher hull speeds and all the small ones stayed home for the day. Upwind we were managing but not very comfortably. The contrast in the Northshore 38’s was interesting as Izzi was handling a larger genoa well while Rainbow was being blown over even with the reefed main.

At the Rose Bay turn mark we tacked away while those yachts that carried on into the bay were rewarded with a very nice lift on the way out. We were not very happy to miss the shift and there was no way to carry on waiting for the wind to shift back so we took a losing tack back into the bay. We were still last on the run and reach around Shark Island and lamenting our position. There seemed no hope of redemption on the work back to the finish off Rushcutters Bay but the breeze lightened a little and we could crank the mainsheet in for more height and still maintain good speed. We timed the last tack back to the finish to perfection and were able to lift up from below L’eau Co and just beat them over the line. Looking around it seemed we had made up time on the fleet so when the results came out I was pleased but not surprised that we scored 6th place on handicap. On the progressive point score we maintained our first place with a lead of nine points and did no damage to our handicap.

The question is how could we have done better? We were not overpowered by much and we could have tacked the No 3 down to the deck. This would have improved the end plate effect and opened the slot between the genoa and main. As an alternative we could have reefed the main at the top mark and possibly taken the reef out for the trip around the island. I like to keep the full mainsail up for the times the genoa is in the wind shadow of the main so next time I will try the genoa hard down on the deck.

At last I am happy with the fairing of the gunwales and have moved on to glassing the deck. I am about a third of the way through and need at least three fine days to finish the deck. In the photo you can see where the layers of glass join and overlap. I am using two layers of a light glass cloth hoping to get a smoother finish than we did on the hull where I used a heavy double bias cloth. The glass cloth was first purchased about 25 years ago when I was building vacuum bagged foam fibreglass NA14’s. I am going to run out before the job is finished so do I buy just enough or get another roll for 25 years supply? On the wet days I have finished the first sanding of the ceiling, epoxy coated the laminated roof beams in the cabin and started sanding the epoxy ready for the first coat of paint on the ceiling. The crew helped fit the Vetus exhaust hose and that took very little time as it went to plan and followed all the planned curves. We also progressed the bits and pieces of timber needed to complete the transom sugar scoop stern. About 24 individually shaped timber pieces are needed and each has to be glued in place in order. It is like having a kit delivered ready to go on the first suitable occasion.