Archive for March 2022

This season will go down as one of the most disrupted with adverse weather conditions. Three of the seven Autumn series races have been abandoned and there has been some did not finishers in the races that were sailed.

I cannot write much about abandoned races but it seems we have become a little too cautious in using as our benchmark a weather station a long way from the club sailing waters and one which is typically several knot windier than our venue.

I do appreciate that for the smaller craft a very cautious limit is wise but for the larger ocean going yachts which are capable of handling much windier conditions they are being deprived of valuable sailing experience.

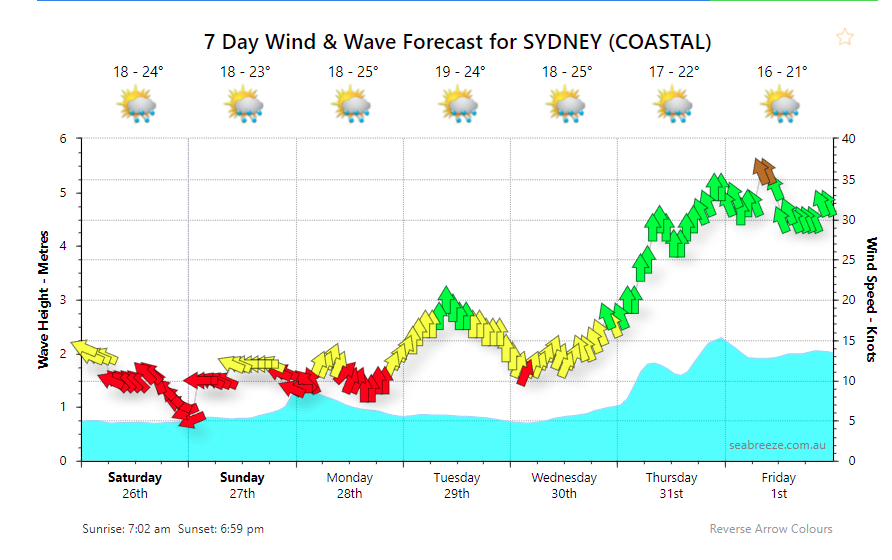

As the season winds up another southerly front is approaching and our plans for a pleasant passage to Newcastle for the Newcastle to Port Season offshore race are up in the air. That is an apt phrase given the shows around 30 knots offshore at the relevant period. It is all going to blow through for the Sail Port Stephens Regatta and it is a pity we cannot save some of the windy weather till then.

Today I glued in place the last of the keel floors complete with pre drilled bolt holts all aligned. It has taken six weeks from starting to cut the timber for the laminations to get to this stage and that seems like a long time. The wettest start to the year for many years did not help with the progress and I have had time off the boatbuilding to go sailing and to do maintenance on Passion X. Allowing for these diversions I still think that there has been six weeks of three and a half days construction per week. In the process I have worn out one saw bench and one random orbital sander as well as investing in a dozen new clamps.

The new saw bench is a great improvement on the old one and I have no regrets that the old one died in service. The random orbital sander was the only one left standing five years ago when buildin Passion X so it had done some heavy sanding. For the replacement I went for a more powerful 150 mm size with 44 % more sanding area which should speed up the heavy sanding on the hull but I will buy a more gentle 125 mm one for the interior sanding. I use a vacuum cleaner to suck up the dust through the sander and it has the added advantage of pulling the random orbital head down onto the work piece.

Drilling the bolt holes piecemeal has advantages and disadvantages. With the limited home handyman tools the full depth holes would a special bit to do the 190 mm depth. By doing each element if the hole is a fraction of a millimeter out it can easily be corrected. For the 85 mm holes through the keel floors I was able to set the floors up horizontal in the drill press and drill most of the way through. The remaining depth was completed by hand but with a deep hole as a guide. So far 145 mm of the depth is completed and the king plank and hardwood spacer on the bottom can be predrilled to the bold pattern and the holes used to pull them together.

There are lots of options for the next tasks and I am leaning towards completing the engine beds from bulkhead F to H and the kingplank from bulkhead C right back to the floor behind bulkhead F. Most of that is under cover and when complete will give a solid backbone.

Another two weeks have passed and the keel floors are still a work in progress. I will lay some of the blame at the feet of the floods or at least the constant downpours but now that the rain has abated and some semblance of normal conditions has returned there must be other reasons.

The keel floors are much larger. They have grown from 80 by 50 laminates on Passion X to 125 by 85 on the new build so there is more timber and much more glue. The easily handled eight layers of 6 mm laminates has grown to fourteen laminations. which I did in two stages compared to the one stage process on Passion X. I think it would be fair to say that there is four times as much work in the timber so I am a bit surprised at how long it is taking. The floors in Passion X are very substantial but with the large increase in dimension there is more floor than space in some sections which means I cannot fit my head up through the gaps to take measurements. On the upside my monkey climbing skills are improving as I clamber out from under the gunwales to up the ladder and along the strong back to check a measurement from above. After a day of this I feel like I have had a very long work out at the gym.

Did I mention how heavy these keel floors are and how I am holding them up one handed while fitting clamps. It must be doing an amazing amount of good and I look forward to the benefits down the track.

All this clamping meant more trips to the hardware store for more clamps for now I have double the quantity I used for the Passion X build.

Being optimistic I am hopeful that once past the massive keel floors the work will be similar to Passion X but there is a bit of work ahead to get to that stage.

A very important stage to get past is the blocking of the keel frames to the hull. For the section between the 85 mm deep laminate and the 30 mm deep strong back I have opted for multiple layers of 6 mm timber across the hull all the way out to the first stringer. I feel this will give me a better bond than trying to infill a 125 mm wide by 44 mm deep space between the floor and the 12 mm plywood skin. For the rest of the infill all that is required is 44 mm thick by 125 mm wide lumber of good quality and that might be four 31 mm by 44 mm high blocks on edge so hopefully that will go quickly.

It is almost three weeks since my last post on the keel floors and not much seems to have happened. We did take a break and drive to Queensland where I helped son Mark with some concrete block retaining walls but allowing for that progress stills seems to be slow.

The front floor which we will call 1 had to be done in five stages as the very sharp bend around the radius chine required a lot of pressure and the most I could manage was two 6 mm laminates at a time. So all up that was one gluing session for the first series of short lengths which form the V and the taper of the floor and four sessions each gluing two more with full length laminates to what had already been glued up. With hindsight which is a wonderful thing we should have laminated the frame before installing the chain plate frames as the shape where they meet clashed with the laminates before they were pulled into shape. So as the laminates were clamped to the previously cured frame the whole structure had to be pushed hard up against the chain plate frame.

I was relieved to get that first ring frame completed and start on the short floors which have a shallow V and a taper from 83 mm down to 50 mm at the outboard end. I found it easiest to glue up the laminates that would form the taper and the V first and then clamp the remaining 8 full length laminates to the curved section on the shop floor. The first six lengths making up the taper are comprised of successively longer sections until the last is full length and that makes for a light laminate that can be handled with ease.

As of the 3rd March four of the keel floors are glued up and a two more have the V and taper section formed and only need the full length laminates glued in place on the shop floor. The last floor is the narrower one that goes under the engine and that is mostly cut. Being narrower it should be easy to handle once the rain stops and work outside can recommence.

If you don’t know what rain I am talking about it is the one in 500 year rain event hitting sections of the East Coast of Australia.

In the first photo you can see a foil section which is the size of the top of the keel. I am making up a drilling template ready for drilling the strongback and the keelson. So far I have cut 4 layers of 12 mm hardwood ply ready to make a 48 mm thick guide to hold the drill bit straight. It is an idea and a work in progress.

After a pretty wet series of Wednesday night the weather on the 16th of February had taken a turn for the better with a warm sunny evening and a fresh breeze. Being a little on the tender side we were a bit apprehensive about our choice of our No 1 heavy genoa but as the race wore on and the wind abated a few knots we made full use of the sail area to notch up another fourth place on handicap.

At the start it was Utopia, Joli and Meridian showing the way. We were next trying hard to stay ahead of Ausreo and Jackpot in the lottery around Greenwich Point. Utopia got into the breeze first and was off like a rocket followed by Joli and Meridian. Jackpot climbed to windward of us and ahead while Fireball did one better and climbed ahead too. From Humbug to Goat Island that was the general order although to be fair we lost sight of the leaders around Goat island the first time and only caught a glimpse of Joli on the second rounding of Goat Island.

Back at the first rounding of Goat Island we somehow managed to get past Fireball and hang on to the tail of Jackpot albeit at a respectable distance. As the breeze backed off a little we had a good run back to Cockatoo island and a work back to Goat island where we seemed to stretch out the gap to Fireball, Ausreo and Sweet Chariot. The main interest for us was staying as close to Jackpot as we could.

On the reach home to Humbug and the work up to the finish Fireball made up a lot of ground so that at the finish we beat her on handicap by just one second with Ausreo just 15 seconds behind.

With the results published it shows what a good race Meridian had being beaten for fastest by just 4 seconds by Utopia but alas the timing was wrong by about 90 seconds. After the presentation where Passion X scored a bottle of wine for third on handicap the results were corrected and Utopia pipped us by a few seconds. So OK Utopia got the points but we kept the bottle of wine.

It was fitting then that Meridian scored first place from Joli and with Utpoia third and just that little bit of luck Passion X was that 1 second in front of Fireball.

Well that was the last of the fine weather as the next weeks the racing was abandoned for lack of wind.

That brings us up to 2nd March which is the first week of Autumn down here in Australia and what a start to Autumn it has been. There have been historic flooding events all the way down the East Cost and we have had and still have our adult children who live in Northern NSW flooded in and waiting for roads to open to restock on food.

The rain has now reached Sydney with the worst expected this evening so it was only right that the sailing was again abandoned if only to keep the competitors off the roads