Archive for November 2021

With help from grandson Otis the last of the large heavy bulkheads have been mounted on the building frame. With a mighty effort by Tuesday evening we mounted the six remaining bulkheads to complete the heavy lifting.

In the gloom of the evening I checked the alignment with the laser level while giving the local mosquitos a good feed.

Wednesday morning I revisited the alignment and noted the keel centre line was not exactly aligned. To help with this final check I used the laser level to true up a plank that could be temporarily laid down the keel centre line and completed the alignment.

It helps considerably to have fitted all the furniture cleats on the workshop floor as these provide a good reference.

The next stage of the build is fitting the stringers so Thursday was spent cutting large planks down to 32 by 22 mm sections for the tangent stringers and cutting 12 mm plywood into 100 mm wide strips where the flat sheets of plywood will meet the curved moulded plywood chines..

With a good soaking forecast I used the stringers cut temporarily hoping to get a cover over the stern. Alas the rain came too soon and too strong for any meaningful progress.

Today despite the frequent showers I cut enough of the main 44 by 22 mm stringers to fill the empty slots in the stern and get a cover over.

So hurried was the process that I did not have time for photos before pulling covers over and retreating from the rain.

Despite the lack of evidence I can report that I am happy with the alignment of all the stringers and she looks very fair and true. On my last build I played with the stringer alignment to get a fair line on them all. This time Dudley had provided much more comprehensive stringer location information so provided the frames are in the right place the stringers will be fair.

Surprisingly we have made reasonable progress on cutting timber. The strongback and gunwales are already cut and the scarf joins prepared. All the tangent stringers are cut and most of the plywood for the tangent stringers. Then about 20% of the main stringers have been cut so there is plenty to do if the rain persists.

My target for this week was to have all the bulkheads mounted and that is done. As for a target for next week that will depend on the weather but I think that I should be able to finish cutting all the stringers.

Since the timber for mounting the bulkheads to the building frame arrived on Tuesday I have mounted on average 1.2 bulkheads a day. Allowing for a day of rest that works out to exactly one bulkhead a day. This might not seem stellar performance but I have also been completing two coats of epoxy primer on each side of the bulkheads prior to mounting. During the week I did a couple of 9 hour days of painting and sanding as well as mounting a bulkhead.

The procedure seems to have settled down to one of mounting a bulkhead with clamps and checking with the laser level before screwing it to the building stock for the duration of the build. Inevitably after the laser level check there is a small adjustment to do the following morning before starting on fitting the next one.

I have fitted all the light bulkheads and from now on it is a two man lift.

Today I would normally go to Gosford to sail the Laser but with a forecast of 5 knots and a very wet Sunday on the way I decided that the priority was to get a tarpaulin over the frames that extend out in front of the awning where I am doing the boatbuilding. That meant finishing the bow instead of installing one of the largest frames. As a bonus I used the front section of the strong back to hold the frames together so that from the bow it is starting to look like a yacht.

Everything has to be done sometime so I like to do tasks when they will add the most value to the progress. Todays tasks included taking the masking tape off the three frames painted last night and shuffling the bulkheads around so that “F” could go on the garage floor for the final reinforcing piece for the engine bed. This is an important frame as it is at the aft end of the keel and takes the grounding loads from the keel. The top of the strongback goes through a 192 mm wide 21 mm deep slot to form a very solid I beam with the 30 mm deep 300 mm wide strongback. When I say it takes the grounding loads I should explain that the I beam ties together the rear three keel floors and the combined three floors take the grounding loads but the keel floor attached to bulkhead F is in the middle.

The next task was to prepare the forward part of the strongback where it bends sharply down to the stem. On the previous yacht I cut half of the keel off and scarfed in a replacement piece as it is easier to bend two 15 mm thick planks than one 30 mm plank. This time because the strongback is narrower at the bow I used the bench saw to cut halfway through the plank sideways and then turn it over and cut the other half. As the plank became wider I did each side in two passes so as not to overload the motor. Once cut from station Zero all the way back to bulkhead A I cleaned up the cut with the hand saw. The whole process was remarkably quick and the slot is clean and ready for gluing back together once bent into the final shape.

Somewhere in this exercise I used the laser level to do a final check in bulkhead E and moved it 2 mm sideways and 2 mm down to its final building position.

With all the preparation out of the way I became a carpenter for the afternoon making up a temporary frame off the front of the building frame to hold the bow. At the same time I could chat to the neighbour who was watering his garden despite the forecast of a downpour tomorrow.

There is a deal of satisfaction when all the elements line up as they should and by 6 pm Elaine was giving me a hand to pull a tarpaulin over the front frames in time for tomorrow’s rain.

Despite the wet weather forecast it is a Club Championship at Middle Harbour Amateur’s tomorrow so it will be a day of boat building.

Saturday is normally a sailing day when I hitch up the Laser and head to Gosford but I have had a bit of a frustrating week with my mega project so that took a higher priority. The tasks for the day were not overtaxing but fate had other plans.

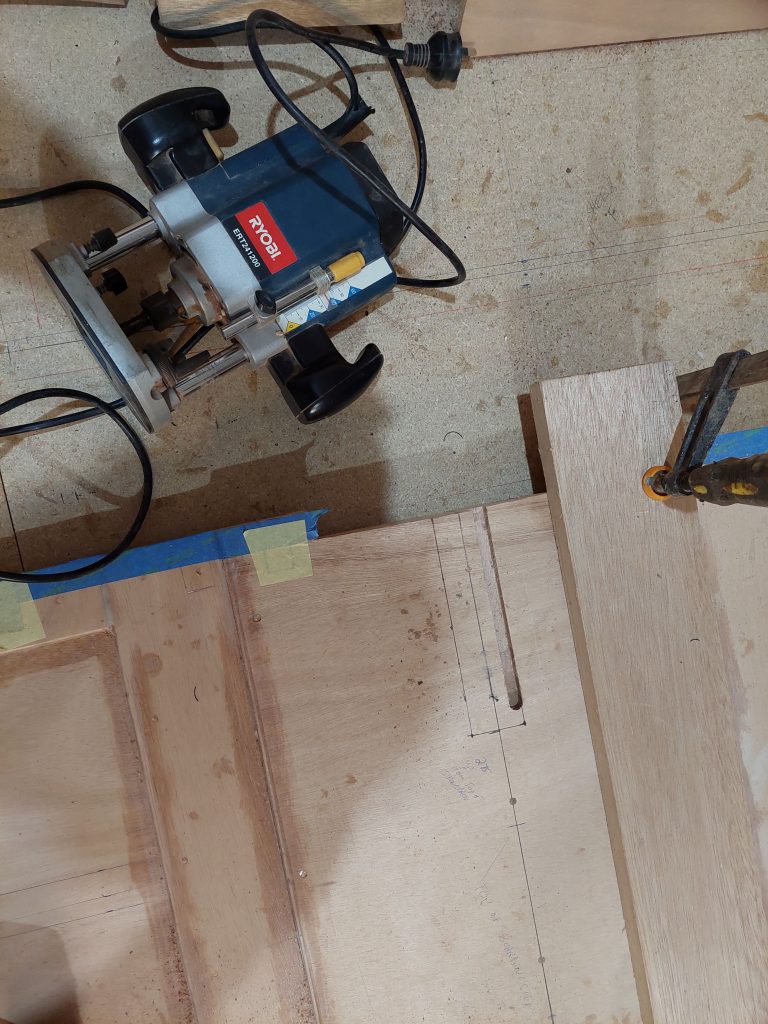

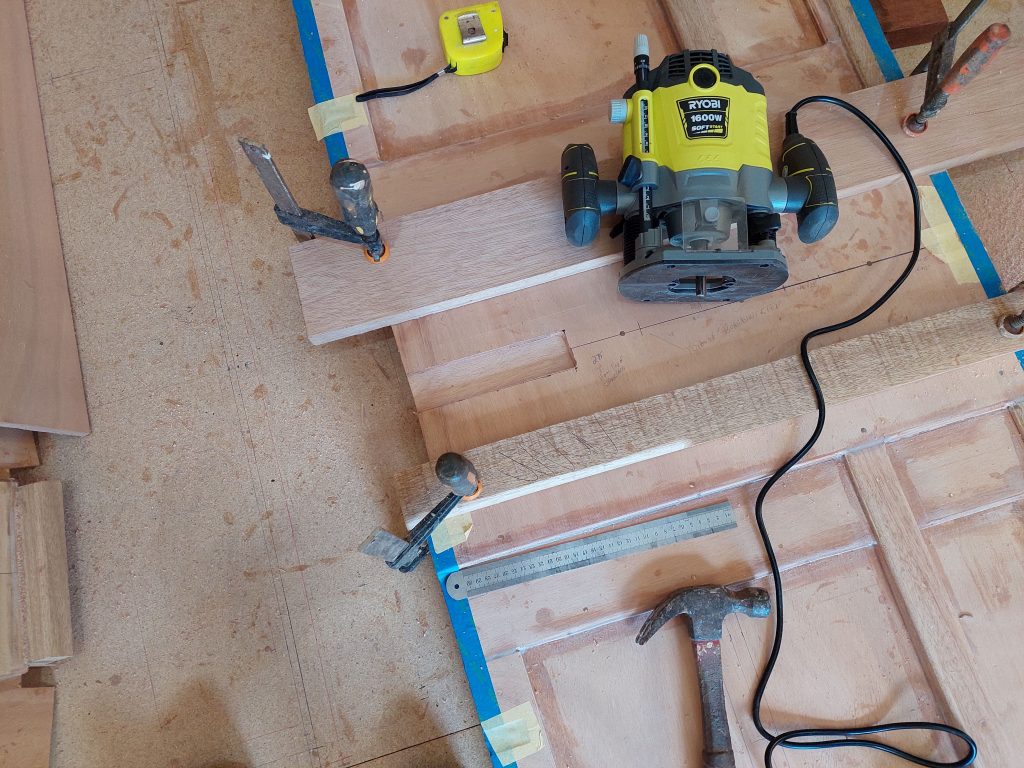

Before I could prime my transom to protect the timber from the weather I had to router a 48 mm wide 12 mm deep slot for the knee. Just a few minutes into this task and the faithful old Ryobi router died. It had a good life building a lot of yachts and I possibly pushed it a bit too hard but these are handyman tools, not life long assets.

A quick trip to Bunnings secured a new, more powerful one but one that fitted my router table well.

Armed with new router and a new found respect for looking after it I soon finished the three tasks, the transom, the mast post and the stem bulkhead.

The stem bulkhead needed further attention as I had to move the station position 12 mm from where I had planned to mount it and that meant a 4 mm trim to the shape. In the calm of Friday evening post the Balmain afternoon pursuit race I set up the stem bulkhead on the kitchen bench and carefully remarked all the positions for the new trim line. That done the execution on Saturday was a mundane if careful task.

The dilemma before me was whether to epoxy saturate the laminate cabin beams to protect them during the construction of whether to start the epoxy primer surfacer on the plywood bulkheads.

As it was a warm day and good for epoxy work I opted for the epoxy saturation first as I could stack the frames and do multiple laminated beams where the white epoxy primer would need shuffling around on the front lawn.

With three bulkheads stacked on the garage floor I was able to get the rest away for the weekend and will leave the white epoxy for another day.

Meanwhile out on the lawn and out of the garage to give me some working room were bulkheads waiting for white primer which never came today. Perhaps Monday will be kinder to these bulkheads

Another Friday afternoon at Balmain and another windy day. It seems that the No 3 jib has been the only headsail to see the light of day. That is not exactly right as we had the No 1 light up for one twilight race but apart from that the Carbon Sports No 3 has been the only headsail used.

With the appropriate level of caution we left the reef in the main from last Wednesday night and made good progress in our pursuit of Irukandji and Odyssey.

Irukandji with a full main started to pull away on the run back from Goat Island so we took out the reef to try to keep up. That worked for the downwind portion of the race but once back on the wind the breeze increased so we struggled with the extra sail area.

Avalon did catch and pass us and we never caught Irukandji so it was a fourth place out of a diminished fleet of six yachts.

I don’t mind sailing with the No 3 jib. It has a very nice shape and covers a reasonable wind range. Also it is good practice for the new Passion that is under construction as she will have non overlapping jibs although about 30% bigger than Passion X

The second night of our twilight series was a windy one with plenty of action so it is not surprising that there are no photos on the Greenwich Flying Squadron facebook page. Sweet Chariot and Passion X opted for a cautious rig with small jibs and a reef in the mainsail and were rewarded with second and third place on handicap. The permanently reefed Ausreo with a lot more weight and waterline took the handicap prize which in the conditions was to be expected.

Third place was what we expected given that we were close to the front of the feet and at the half way mark were mid fleet on fastest times.

Our small crew did well under the circumstances and we did have a little luck with the phasing of the shifts around the healands.

Back at the garage most of the bulkheads have been finished and the final touches may happen tomorrow.

Planks of Meranti have been selected for the backbone and all the timber for the gunwales has been cut. I did make up a giant mitre box for cutting the splice angles on the 32 by 100 mm timber but I will need a much longer saw to be able to use it. On Passion X the Makita power planer was used to cut all the splice join angles and I am still experimenting with this one.

When the weather is right I have a stock of timber to cut into 22 by 44 mm stringers so there is plenty to do.