Archive for February 2015

In the early morning rain I went about preparing some inside jobs including rearranging a support so that I could complete the shelving in the quarter berth. When the rain stopped I moved outside and did a final fairing of the stringers up past the mast step ready for planking. Two of the crew from Passion arrived through the morning and by midday we were well into the first layer of 6 mm plywood on the radius chine.

With the jobs shared out between marking, cutting, planing and drilling work progressed at a pace and to a high standard. Two extra pairs of eyes were good at spotting places where an extra cleat was need to hold the ply down and by 5 pm we had nine planks fitted and glued. We are now well forward of the 800 mm radius at the mid saloon station and are moving up to the front berth and still managing to bend the 6 mm sheets into position. Two extra pairs of hands helped and it will be interesting to see how I manage alone on the other side of the hull.

The photo at the end of the day shown the extent of planking on the starboard side and also shows four planks of the second layer at the stern of our Didi 40 Cr.

Today was a bits and pieces day. The early drizzle prevented me applying the last coat of potable water tank lining so I ventured under the hull to complete the glassing in of the chainplate frames. Both sides are now glassed in with four layers of 425 gram double bias on both sided of the frames. The structure is looking strong and when the 6 mm plywood saloon back rest is epoxied into the shelves it will form a very stiff box structure. Just as the glassing was completed the rain stopped so I was able to complete the tank lining. When I say complete I mean what can be done before the hull is turned upright and the tank sides glassed to the hull skin. Because of the wet paint I could not proceed with more of the first 6 mm plywood layer so I started a trial of the second layer of 6 mm plywood at the rear of the hull. The angle grinder was used to clear us excess epoxy from the rebate. The rebate plane was used to fair the section and the join between the rebate and the first 6 mm plywood layer. Next the plane was used to take off a small high spot and finally a torture board used for some light final fairing. The photo shows the surface before the second layer is added and if the second layer finished as fair as the first I will be very happy.

In the afternoon I was able to install the first four 280 mm wide planks at 20 degrees to the first layer. Because of the 20 degree angle each planks cover a 300 mm length of the hull so I can reuse my plywood clamps from the first layer to secure the ends of the second layer. I did not get my target 8 planks a day completed but the other tasks made if a full days work.

Each post I usually include the name of the yacht design the Didi 40 Cr and I include that in the photos. I do this so that Google and other search engines can locate the posts and images.

With the arrival of Agrovation last year and Saoirse this year to join with Worlds Apart as bigger longer faster yachts our proper place on fastest time is probable fourth. Last night we hung on for a fourth fastest in very light conditions and we should be content with that. Unfortunately as Martin noted we have a crew of Laser sailors who want to be first.

While it was a frustrating night being caught in various wind shadows it was still a very enjoyable one and post race when the adrenalin settles down you realize how fortunate we are to have the opportunity to sail in such testing conditions on what must be the best twilight sailing area in the world.

We set our largest genoa which is best for reaching and running and used it to good purpose in the light dying conditions at the end of the race to stay ahead of the following pack and almost catch Saoirse. Worlds Apart bolted at the start and was not to be seen all night. Agrovation was naughty at the start which left us in their dirty air all the way through Humbug. We stayed in touch with Agrovation all the way around Cockatoo and on the way to Goat Island but lost her on the Balmain shore when I was too timid to tack in front of the ferry. The extra few meters needed to clear the ferry left us in the wind shadow where we languished until Agrovation had drawn away and Tartan, Gwizz and Saoirse had sailed past. Eventually we edged out of the wind shadow and took off after the five yachts in front. Now we were running and reaching and using the large genoa to advantage. On the long slow reach back to Humbug we managed to overtake Tartan and Gwhizz while Saoirse used her long water line and large sail area to power away. French Connection put in a late appearance down to leeward but we managed to bear away in a puff and get clear air to windward of her. In the last run to the finish line Saoirse found her own patch of light air while Kevin held our big genoa out to windward so we almost caught her on the line.

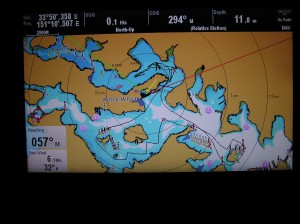

The tracks show we did some pretty nice angles out of Humbug on the way to Cockatoo Island and if you look have in the bottom right corner you can see a little deviation when we almost tacked but found the ferry dead in front so had to go back.

The clamping arrangement for the first layer of 6 mm plywood on the radius chine of the Didi 40 Cr has worked well. With the help of a crew member we made up lots of clamps from 280 mm long by 50 mm wide pieces from 12 mm ply. These were predrilled to be a loose fit on a 10 gauge self tapper so that when the self tappers were screwed into the hull the clamp would come down on the 6 mm ply. When fitting the radius chine 300 mm wide strips of 6 mm ply the top clamp was loosely fitted to form a wedge into which the 6 mm ply would fit while the tapers were planed on the strips as required to follow the hull shape. Once the tapering was completed the 300 mm wide plank was glued into position and the clamp on the lower chine pressed hard against the hull while the self tappers were driven home. The self tappers are in line with the stringers and go through the 6 mm rebated of the 12 mm ply flat sections plus the 12 mm of the ply doubler and so far non have pulled out of this 18 mm thick ply section. Once the lower join was completed I then tightened the three self tappers in the upper clamp and then clean up any excess glue before moving to the next plank.

The photo shows a clamp removed and the good tight join left behind. The back side of the clamps are covered in packaging tape which is an excellent mould release material and I have shown the removed clamp next to the join.

First layer of the 6mm radius chine with the clamp removed showing the tight join and the packaging tape on the back side of the removed clamp

The first layer is progressing towards the saloon area and I have had to slow down the planking to complete the potable water tank lining before covering the water tank area. I have now moved around the fattest most curved section of the hull The shadow of the hull on the sides shows that it is very fair even before any sanding prior to the second layer.

The shadow on the hull shows that the radius chine is a series of flats and the high edges will be lightly sanded prior to the second layer.

Today is Ash Wednesday which for Catholics in Australia is a day of fast and abstinence.

Well it was not so fast for us on the race track nor for fellow competitor Farrst Company who ripped a genoa during the race. What was fast was the incoming tide and a new Dufor yacht, Van Demon, that joined the fleet for the first night.

It was an unusual race with a fresh sea breeze that gusted and shifted only to die in the closing minutes of the race while the fleet struggled through Humbug. We set the most sail area we could anticipating a run for the first leg but the breeze was so strong that the fleet sailed at hull speed for the first leg.

Our normal leeward side approach to Cockatoo Island did not pay off as a fresh gust reached the windward yachts first carrying them around the island ahead. In an uncharacteristic following mode down the side to Cockatoo we struggled to find a gap but did manage at the rounding to find a spot to leeward of Gwhizz who appeared to be reefing the main. Further out from the Cockatoo Island wind shadow Agrovation sailed into the breeze first and held that gap all the way around the course.

On the work against the tide up the Hunters Hill shore Van Demon picked a great lift off the eastern end of Cockatoo and got a big jump on the fleet. Meanwhile Izzi was up in the leading bunch tantalizingly within reach if only we had a favourable wind shift.  Tonight was not the night for the dice to roll our way. We could not bear away behind the stern of the black fleet Young 40 and so had to put in a short tack just as we were catching Agrovation. We just missed turning marks by a boat length and has to tack on three occasions but the biggest knock was reserved for the finish line where we were knocked and fell half a boat width too low only to be knocked on the tack almost back where we came from.

Tonight was not the night for the dice to roll our way. We could not bear away behind the stern of the black fleet Young 40 and so had to put in a short tack just as we were catching Agrovation. We just missed turning marks by a boat length and has to tack on three occasions but the biggest knock was reserved for the finish line where we were knocked and fell half a boat width too low only to be knocked on the tack almost back where we came from.

A strong incoming tide carried us towards the line ahead of the following fleet that was not reaching towards the line. Tartan approached the finish line at 90 degrees to the angle we had and so any semblance of a good performance by Passion was blown out of the water.

Back on dry land the boat building progress on Next Passion was also not going fast. My ambition of 16 planks a day has been halved and that is for a full 8 hour day. Final fairing of the radius chine section is taking longer than expected but the time spend is paying dividends with the curved sections matching as well as could be expected.

I was keen to start the moulded ply section of the hull because I was concerned that my 6mm plywood might be too stiff for the task. Dudley recommends 3 ply while mine is 5 ply hardwood and quite a bit stiffer. After a bit of experimentation I settled for clamping the 6 mm ply to the doublers using 12 mm ply clamps secured with large self tappers. The hull side of the 12 mm ply clamps is covered with packaging tape so that it will not stick to the hull.

I also made up a very precise 788 mm radius template to check all the doubler angles and stringer contact points. Because the stern where I started the radius chine ply has a very flat run great care is needed to keep the run straight.

The neighbour watched the progress all through the day at as evening fell he gave it a nod of approval.

Due to some very nice weather Friday afternoon and Saturday morning I was able to finish the last two panels on the bottom of the hull. I did spend a lot of time fairing the keel, stringers and ply doublers so it is no surprise that the glue joins are close and well filled with epoxy adhesive.

In the week since finishing the side plywood I have completed 75% of the bottom plywood panels. I may miss my self imposed target of completing all the bottom ply this week due to an unexpected commitment but I am happy with the progress.

75% of the Didi 40 Cr bottom ply is complete. This view shows the shelves in the quarter berth already installed.

The weather has warmed up and that makes gluing in the middle of the day impractical. One sheet before 10 am and one sheet after 5 pm is about the best I can manage. Also working in the sun on top of the hull in the middle of the day is not that enjoyable so today I took off in the air conditioned comfort of the car and purchased my potable tank lining epoxy paint. I want to apply as much as possible from the outside and just leave the hull inside to complete after the moulded ply round section of the hull is finished. I have chosen Interplus 1180 and the left over will be ideal for interior areas I wish to finish in white such as the engine bay. Between purchasing the potable tank lining epoxy and fixing the second sheet to the bottom I spent some time preparing the tank interior for the paint. I have lined the plywood with 225 gram woven cloth which I have overlapped at the corners over the interior triangular cleats so the surface has minimal tight corners and should be relatively easy to clean when required.

I am waiting for the glue on the last panel to cure before pulling the tarps over for the night so I took some photos for the record. The first one shows some detail of my fibreglass reinforced joins where I have 850 grams per m2 of glass on both sides where I am looking for every millimeter of space for the stainless steel diesel fuel tank.

Epoxy glass corners have been used where I need a square finish for the stainless steel diesel fuel tank. The corner in the background also has a 25 mm triangular timber cleat on the other side. I have made this double secure because the wider cockpit of my wide stern version is cantilevered from the other side of the join.

The last photo shows the chainplate frame already installed, stabilized by the 6mm ply shelves and with the hull ply sheeting already glued and screwed to the frames. The frame has still to be glassed to the hull and I am saving a lot of these jobs until I have the ply bottom finished and can tidy up the garage. I don’t use it as a timber workshop and a glass workshop at the same time for fear of contaminating the rolls of glass. Also these will be ideal wet weather jobs once the radius chine is completed.

Tonight we chose the big black genoa despite the wind gusting pre race to over 18 knots. We reasoned that the breeze would die as it does most evenings and I was encouraged by Frank’s support to go for the big one.

We won the reaching start and poled out for the long run to Spectacle Island. A big header made the poled out geonoa less effective than the genoa set to leeward but we hung on to shave Clarke Point by a barnacle and a half. Bearing away we had the fleet behind and a full dose of dirty air from six keen followers. Izzi managed to blanket us and nudge in front around the island but we hung on to their stern all the way to Snapper Island and rounded up harder to have a windward position on them. Izzi tried hard to pinch up under us but the large genoa gives us power and height to hand on in a pinching contest so eventually we prevailed. On the beat to Goat Island we picked the shifts pretty well and also put a loose cover on Izzi.

Around Goat Island we went closer to the leeward shore than usual to discourage them from going above us as they did last week. The strategy paid off as we were able to keep clear air and stay ahead.

The reach back to Humbug was in fresh air and Saoirse was powering along looking for a passing lane above while Izzi was charging along to leeward looking for a passing lane there. Again we were forced to go closer to Greenwich than we usually dare but it paid off with us maintaining the windward position into Humbug.

The course the line was a tight beat so we covered both Izzi and Saoirse and held on for a fastest time by the slimmest of margins.

The rest of the fleet did well to catch the three leaders on the way home so for our efforts we scored a second last on handicap.

Final fairing of the keel before fastening the plywood took longer than expected so I managed only two ply panels on the bottom today. As well as the final fairing I set up the keel bolt templates on the inside and outside of the keel, checked that they were positioned correctly and opened up the pilot holes. This task was on my job list to be completed before the plywood is secured over the keel area. It is taking longer to trim the keel than I expected so I think it will take another three days to complete the bottom panels.

The new build is now covered with 12 mm plywood from stem to stern and from gunwhale to the radius chine. I have been very pleased with the progress and on Tuesday last I fitted four sheets in a long working day that finished in moonlight.

Today the fairing of half of the bottom was completed ready for the first ply sheets. Dudley says not to fair the keel to far ahead of fitting the plywood if you are working outside so I am sticking to his recommendations. A really sharp had saw is ideal for establishing the level across the keel and stringers

I am also doing the two sides together. Once the first side is cut and trimmed to the radius chine line I use it as a template for the second side and so far that has worked well.

Some of the off cuts from the side panels will be large enough for the smaller bottom panels so there will be fewer full sheets to carry back and forth from the hull to the workshop.

As a bonus item Dudley has a new post on his blog with a really good photo of the prototype Black Cat.

You can read the article here

http://dudleydix.blogspot.com.au/2015/02/what-saints-did-next.html

The original article with more photos can be read here

http://whatthesaintsdidnext.com/2015/01/30/black-cat-champion-race-yacht/comment-page-1/#comment-81

You will need to scroll up from the comments to the top of the article to see the photos.

Wednesday was a good day to pick up Passion from Noakes and return her to her mooring at Woolwich. I arrived at 7 am and Passion was in the travel lift ready to be launched. In quick time she was back on the mooring and I did a bit of housekeeping while waiting for Elaine to taxi me back to Noakes to retrieve the car. En route we had coffee in Blues Point Road and a chat with one of our sailing friends before heading home.

The forecast for the evening race was for around 20 knots so the No 2 genoa which was already on the furler was the logical choice. The smaller genoa worked well while the breeze was fresh and we were comfortably second behind Saoirse, the Dehler 38 with the unpronounceable Gaelic name. In the lee of Cockatoo Island on the tight reach to Goat we were run over by Izzi and French Connection who found some breeze in the lee of the island. Izzi soon dropped on us and gave us all the dirty air they could find while we pinched up to pull clear ahead of French Connection. At the clearance mark at Goat Island we were dead ahead of French Connection with a lead of 20 metres when a big lift put her alongside and we were forced to tack behind her stern. She promptly tacked on us and started to bear down to give us her dirty air. We were pinching as high as we could to clear the island so we could not force her higher but neither could we tack away from the shore. I don’t know how we cleared the last pylon but we managed without being knocked onto port into French Connection so we lived to fight another day. Now we were chasing three yachts. Izzi had made up a lot of ground on Saoirse but could not bridge the last gap. Fench Connection was just ahead and we had every intention of blanketing her once around Onion Point but alas the wind would not cooperate. We found our own private wind eddy and stalled while they took off and lead us over the line by a minute and a half.

As disappointed as I was with the result I felt for Gwhizz who got separated from the leaders and never made it back to the top group. Avanti who had been sailing well the past few weeks was also well behind so mid fleet was not a bad result for Passion given the fading conditions.