Archive for May 2015

I am a fan of the West Harbour Winter series conducted in the area between Goat Island to the east and Schnapper and Spectacle Islands to the west. This is our second season and with every race the crew is more comfortable with launching and retrieving our big red white and blue spinnaker and in gybing it downwind.

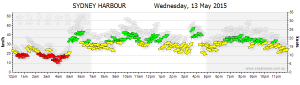

Today was a typical event conducted in a light westerly breeze well below the forecast fifteen knots. Both our yacht instruments and the weather bureau seem to agree it was about seven knots at the good times.

We started near the boat and gave way to yachts that by rights we should have forced into the committee boat. For our efforts one crossed early and was disqualified for not returning but we had to eat the dirty air up the first work. The breeze swung to the right favouring the more northerly positioned yachts and that was not us so we had to tack away from the lifts on two occasions which do not look pretty on the chart plot of our course. As the day went on the breeze swung more to the north so the second work along the Hunters Hill shore was a single beat compared to the zig zag tracks of the first work.

The fun bits were flying the spinnaker around Schnapper Island and then carrying it tight along the Balmain shore.

Our twilight competitors Saorise and French Connections were left well behind on the first work and I assume they did not have spinnakers flying by the look of the elapsed times. A few light weight flyers from the blue division caught us and Gwhizz took a minute out of our time in conditions that suited them. The J 70 caught us on the downwind legs but we managed to stay with them from Goat Island all the way back to the finish line.

The last run to the shortened course finish line was very square and our big symmetric spinnaker worked better than the asymmetric on the J 70 as the conditions were too light for her to get up and plane.

Our sixth place on handicap was pleasing as was our elapsed time compared to our regular competition.

Today was spent planing back the ply doubler on the backbone to reestablish the “V” shape on the bottom.

Even with the aid of the Makita power planer it was still a lengthy job and much hand planing was needed for the final adjustment.

Power and hand planers make a lot of wood chips reestablishing the “V” on the bottom of our Didi 40 CR

I managed to finish from the keel to the transom including belt sanding the doubler to make sure it was flush with the ply bottom. Tomorrow weather permitting I will try to finish section from the keel to the stem.

In drifting conditions we scored first on handicap today. The conditions were ideal for Passion as we were able to pole out the big genoa to leeward at first and then to windward later on the downwind leg and the windward work was a short one to the shortened course finish line.

We started well at the boat end in less tide than the windward yachts and maintained our position near the front of the fleet for the downwind leg. Several times our competitors crossed us looking for breeze on one side of the course or the other while we kept a more conservative track. I moved the sailing angle around with the breeze quite aggressively to keep the air flowing over the genoa and that seemed to pay off rather more that chasing the breeze on the sides of the course. Amanti, Allegro and Larrikin all crossed within metres of us but suffered by going in too close the south head shore.

Fidelis managed to get out in front criss crossing the rhumb line while Britannia managed to pass us with a similar pole out to leeward and windward strategy. When I say pass us they just had the clear ahead position at the turning mark as we had to swing wide to avoid them. That allowed Allegro to round tighter and sail over the top of us on the windward return to a very shortened course. Kevin spotted a lift ahead so we tacked for the breeze and managed to cover most of the fleet. The extra width to windward allowed us to keep Passion moving to the finish line just ahead of Agrovation. In the short work to the finish line Allegro gained a minute and twenty seconds on us which shows how well she travels to windward.

For the first time ever we beat Amanti, a Sydney 36 cr over the line so we knew we would have a good handicap result. Agrovation managed a good second on handicap so it was a good day for the Jeanneaus.

The hardwood shoe which fits between the hull and the steel keel is fitted to the hull. It sits on top of a 2 mm thick layer of high strength epoxy glass which is part of the additional reinforcement I have included in the construction of our Didi 40 CR. I had already drilled pilot holes for the keel bolts but I checked and rechecked every part of the way as I drilled the full size 25 mm holes through the keel and keel support frames.

It took the best part of a day and a half to drill the eight holes, fasten the hardwood shoe down with two of the keel bolts and prepare the plywood capping for the centre line reinforcement. The photo shows the two keel bolts temporarily holding the keel shoe until the glue dries. The bolt have been wound around with packaging tape so that they come out to the full diameter of the holes and there is no movement of the shoe while glue sets. The packaging tape is also excellent mould release material and the bolts should be able to be removed even if some epoxy had oozed onto the tape.

The plywood capping pieces have to be shaped around the keel and also splice joined along the length so it took a couple of hours to do that effectively. Tomorrow the plywood will be glued down ready for the final shaping back to the original hull “V”. Also completed is the reinforcement where the 70 mm diameter stainless steel rudder shaft goes through the backbone. Two pieces of spotted gum hardwood have been glued in either side of the backbone making a very solid structure to support the loads on the rudder shaft.

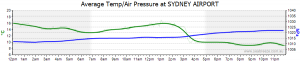

As I took a break from boat building to contest the RANSA Winter Wednesday race the weather turned sunny and warm with just enough breeze to compete a shortened course finishing at the Point Piper mark.

We debated about which end of the line to start at. The easterly breeze could be seen filling in across the course from the north and from the east. The compromise position was that we would start at the boat end and use the better angle to get across to the north as quickly as possible. At the gun the breeze hit the boat end of the line and as it was a header we went with it as it was freshening ahead. The first tack back gave us a good position near the head of the fleet and from there we played the breeze as best we could. We wanted to stay in the tide and that did pay off when the breeze lightened but in the gusts the shore off Watsons Bay had better angles.

Agrovation played the shifts well and jumped out a minute or so on us while we were in close company of the three Northshore 38s Izzi, Rainbow and L Eau Co.

On the reach back we poled the genoa out to leeward and the wider slot worked well as we made up ground on Mercedes IV and Agrovation. By Steel Point we were neck and neck with Rainbow and L Eau and Co and just managed to hold them out for an inside position at the Rose Bay rounding mark.

About now what breeze we had dissipated. There was about two knots from behind to keep us moving and as we went high to protect our position we found a little more pressure which enabled us to leave Rainbow and L Eau Co behind. Agrovation went further north for the breeze but the extra distance they travelled brought them back to our position.

In the dying breeze the slower yachts on the day were punished with even longer times to cross the finish line so we did well to take a couple of places on handicap and finish sixth.

Our light No 1 genoa with the big overlap is well suited to the light airs and square running with the genoa poled out on our long pole so it was the right rig for the day.

I have had a very lucky day with the weather and managed to lay up most of the glass reinforcement on the bottom ply that supports the keel loads. The reinforcement is 2 mm of high strength epoxy glass which I have taken out to the position of the water tank sides which support the keel frames. Length ways it extends for three metres from the mast step to the end of the engine beds. The layers are stepped so that there is not an abrupt change of 2 mm in the skin shape. Peel ply over the edges of the glass ensure that the edges are held flat and there will be minimal clean up once the peel ply is removed.

The area for the glass reinforcement includes two butt joins where I have planed out a step to allow an extra heavy layer of glass to reinforce the join. All up the join is covered by 2.75 mm of glass so it is far stronger than needed. The photo shows the butt joins prepared for the heavy glass strap and the ply hull sanded down ready for the glass reinforcement.

On the luck with the weather story Monday was very frustrating as every time I removed the covers to start glassing the drizzle would start so the day was spend running errands and epoxy saturating the inside of the hull. The forecast for Tuesday was no better and heavy showers were forecast for 1:00 pm in West Pennant Hills. Hoping to beat the rain I started early and laid up a couple of layers of glass then covered the boat waiting for the rain. Over morning coffee the sky lightened so I tackled the next section successfully. The final bit of risk taking was to gamble that the rain showing on the rain radar would go just south of West Pennant Hills. The last section I glassed was the final three layers of glass on the front half of the keel area. I had just finished spreading the resin on the three layers when a few spits of rain started. I quickly covered the resin with peel ply and had enough time to remove all the air bubbles, smooth out the glass under the peel ply and pull the covers back over before any serious rain started.

Our small loyal crew of four enjoyed a quiet but entertaining afternoon chasing wisps of wind around the west harbour. The breeze was true to forecast at around three to seven knots with some very big shifts to reward those who went the right way. In our case the right was was to keep Passion moving and we succeeded on several occasions by going lower and faster to the new breeze. The highlight of the day was setting the big red white and blue spinnaker for the legs back from Goat Island to the shortened course finish at Cockatoo Island and in the process holding our the Adams 10 Boxer.

Early in the race we were hindered at the start but once away we started to catch the rear of the yellow fleet and were well amongst it after the run down the south side of Cockatoo Island. The downside from the hampered start was the leaders of the blue fleet catching us and giving us more than our fair share of wind shadow on the square run behind Schnpper and Spectacle Islands but to our delight we managed to round just in front of most of them and promptly worked away with some good lines up the north side of Cockatoo Island on the long work to Goat Island.

On the return from Goat Island to Cockatoo mark we were happy for an early finish as the wind died completely thirty minutes later. In our division we finished across the line ahead of five yachts and were rewarded with an eighth place on handicap out of the fifteen starters.

The two meranti capping pieces have been glued and screwed to the stem post on the new Didi 40 Cr and the last two small sections of ply have been screwed and glued so the front end is looking more complete. Behind the butt join of the plywood along the gunwhale at the stem I have crafted backing pieces of 12 mm ply with parallel 45 degree bevels. One bevel sits on the angled gunwale timber while the other makes a nice transition from the 12 mm single layer to the two 12 mm double layers. This little extra strength will come in handy if we ever attach a fixed bow prodder through the double walls of the anchor locker.

At the stern I have joined the two bottom plywood panels that extend past the transom with a neatly angled 12 mm plywood doubler and so all the hull is complete except for the capping piece along the keel center line and the glassing. On the procurement side the keel fabricator has been selected so I have move on to the engine selection. I was delighted to learn that the new Yanmar 3YM30ae has the 125 amp alternator, up from the 80 on the 3JH4e we have on Passion. Also I have done some speed and power calculations and estimate that the new build will be a knot faster than Passion despite having a smaller motor. The fibreglass stern tube for the prop shaft is on back order so I should get the engine bearers organized so I can align the stern tube when it arrives. Still on the engine side I have managed to source a Radice shaft seal which has a water inlet built into the seal. That will allow me to put the cutless bearing right at the top of the stern tube securely centered around the frame support and have cooling and flushing water going through the top cutless bearing and out the stern tube. A the top of my current job list is doing the capping piece along the keel line and the keel hardwood landing. I have a nice piece of spotted gum for that job and while it is heavy it is very solid and will provide great crush resistance against the load of the keel bolts.

With the winds forecast to be around 20 knots we set a conservative rig of the No 3 genoa and a full main for the RANSA Winter Wednesday race. The course suited Passion better than last week as we were able to pole out the genoa and follow the wind around the course. The breeze for the downwind leg had a lot of holes and we rarely saw the forecast 20 knots. We rounded the turn mark behind Viva and L Eau Co and were promptly rewarded with a large lift that made us look good as we lifted above these two. When the wind headed we were forced back into L Eau Co’s dirty air as they were determined to pinch out from under us. We tacked away to take advantage of the knock and that is the last I remember of L Eau Co on the course. Izzi was a little ahead and the Jeanneau SO409 Solange was just behind so we had plenty of company to race up the course. The shifts to windward were so great that we were forced to tack on the knocks and the smaller headsail helped to get the tacks done in an orderly fashion. Around Steel Point we were unlucky to get a knock that required us to tack away from the rocks while those a few metres ahead had already cleared the rocks and could take advantage of the slightly more free work into Rose Bay. We got a little of this back in the approach to Point Piper where we kept some room in reserve and just cleared the mark while Izzi and Larrikin had to tack back for the rounding. Around the island Larrikin cleared out but we kept in touch with Izzi and just ahead of Solange. The last beat to the finish was in two parts. The first was a quiet before the storm when the breeze dropped to seven knots and we struggled to keep Passion moving with the No 3 genoa. This is probably where Larrikin gained time on us and certainly when Solange with a larger genoa moved up alongside and to windward. As the breeze freshened it lifted giving Solange a free kick. We in turn lifted inside Izzi and as the lift progressed we made up some of the ground lost in the light airs. Now the breeze honked in at 30 knots accompanied by icy cold rain. Ron had the mainsail dumped and flogging in the slipstream of the air from the genoa. I had the backstay on hard to flatten the main as much as possible and we enjoyed the ride to the finish line.

In the finish we had Rainbow, L Eau Co and Enigma well behind and were within seconds of Solange and just a little behind Izzi so we were happy with the result. On Handicap we scored 7th out of the 14 starters which is a big improvement on last weeks second last. We benefited from a clean bottom but the divers said it was in good condition and there was nothing to explain last weeks performance. I will stick to my proposition from last week that Passion does not like the broad reaches where we cannot set the pole.

The fine weather has returned and so I am able to recommence the fairing of our Didi 40 Cr hull. When there is no breeze the belt sander does a good job of leveling the local high spots around the plywood planks on the radius chine. If the wind starts blowing in the direction of the neighbours I switch to a hand plane. A long heavy fibreglass batten and a lighter aluminium angle have proved very useful for locating high spots that need a little trimming.

As reasonable progress has been made with the initial fairing today I made up a new torture board and have been up and down the port side. There is still a little to do on the port side but it is starting to look pretty fair. I tried spreading blue chalk on the hull and sanding it away with the torture board and that seems like a pretty useful technique except is is probably too exacting for this stage as we have yet to glass the hull and then will need to do it all again.

Yes sadly we performed very poorly on Wednesday with a last fastest and a second last on handicap. The divers will check the bottom before the next race but as it is not long since the last antifouling I do not expect they will find much wrong.

On the first down wind leg we were not well positioned for the gusts that seemed to pass to windward and not come over the course. Gwhizz and Star Ferry both now in division 2 started five minutes behind but by half way down the leg had all but caught us and L Eau Co. Now reaching is not our strong point and it was an awkward broad reach where we had difficulty flying the genoa as well as our competitors. We had the black carbon genoa up which is great for windward work but does not seem to fly so well on the light air reaches.

When the breeze did set in for the work home we were already well back. L Eau Co pointed higher and soon passed us. There were some huge shifts on the way back to the finish line and if we had been on the right side of two of these it might have been a less somber story.

Apart from our individual place I have no more details as the results are not out. The previous system worked well but someone thought they might fix a not broken system and now it is fully broken.

Many weeks have passed since any meaningful progress has been made on the new Passion, my Didi 40 Cr. The planned breaks to sail the old Passion at Port Stephens and to visit relatives in Perth have been extended by the prolonged wild and wet weather in Sydney. Boat building planned for the intervening periods was difficult and even the inside jobs were hampered. On returning from Perth we had to bring Passion back from Port Stephens and were fortunate to do so on two of the four dry days since the rains commenced. Most of the stranded fleet made it back in the previous two day window and one adventurous pair even managed to finish their return voyage with a race in the GFS Saturday series which they won.

Since we returned last Thursday there has been more heavy rain so work has been restricted to what can be done in the garage and procurement of fittings. The rudder is fabricated from nine layers of plywood and seven of these have been cut to profile ready for joining. The central 12 mm panel is surrounded by the 70 mm rudder stock and 12 mm stainless steel tangs which provide the turning moment for the structure. There are just two more small 6 mm panels to be cut to complete the set but the joining to the stock must wait until the rudder bearings are fitted to the hull in the next dry spell.

The weather is forecast to be dry and sunny for the next six days so hopefully the covers can come off and the fairing continued where we left off a month ago.