Archive for January 2016

On Wednesday I took a chance against the forecast and glued on the last 12 mm panel on the transom below the boarding platform. For good measure I sealed the ply edges with thickened epoxy to keep out any moisture overnight. Today I trimmed the surplus ply on the underside again epoxy saturated the edges and face of the ply with wet on wet coats of fast cure part B. The cure beat the thunderstorm that rolled through late in the afternoon.

I managed a coat of epoxy primer in the locker and have just one small section behind the quarter berth to sand and prime. It is already double coated with epoxy and the white primer is to improve the light in the dark corners of the hull.

In between jobs I bogged some 100 mm wide 12 mm ply strips to the top of the frames I am building to support the hull after the turn. Tomorrow I will add a couple of layers of glass for good measure and then pre drill the frame ready to bolt to some solid LVL planks.

Two support frames of 24 mm ply shaped to the hull and with 100 mm wide ply planks to spread the load.

Our No 2 genoa started life as a cross cut flex kevlar laminate with taffeta on one side and we had some good races with it but I felt the flow migrated too far aft. We had the sail retro fitted with carbon strings and that has made it into a very stable shape sail which we use in over fifteen knots of breeze. Over the season I have progressively moved the genoa cars further forward and that has helped with more drive low down and more even streaming of the tell tales. The clew now hugs the deck and while the sail is only 35% overlap we seem to generate good speed with it. As the overlap is shorter we can tack faster and that was put to good use on Wednesday night.

We made a good start although Kevin said we could have fitted the whole Laser fleet between us and the line at the gun. Despite that we crossed the line with speed and made it first into Humbug. The last we saw of Jedi was Ray telling us the course before he took off for another fastest time. Worlds Apart powered over the top of us off Greenwich Yacht Club so we had to follow in their dirty air. On straight line speed Izzi was below and in front and French Connection above and behind but not for long. French Connection used the height to advantage approaching the navigation mark off Goat Island while the rest of us slowed pinching to avoid a tack. By avoiding the tack we passed Izzi and managed to stay in front for the night. Around Goat Island I sailed high enough to stop Izzi going over the top but Farrst Company sailed through to leeward and Worlds Apart and French Connection opened up a sizable lead. In the run back around Cockatoo Island we sailed low and slightly be the lee to keep clear air and were able to pass Farrst Company and keep Izzi at bay.

The work back to Humbug and the finish line was where the ability to tack the No 2 genoa was put to good use. With Kevin calling the shifts we tacked on the headers and made up the sizable lead that French Connection had established around Goat Island. At the same time we drew away from Izzi and Saoirse. Farrst Company had a little altercation and did a 720 which put paid to her handicap chances for the night and explains why she dropped so far behind. Agrovation will have a clean bottom next week and will be back in form.

What a difference a day makes. Contrary to forecast the day was perfect for boat building and gluing in particular. I was still thinking of my friend Bruce who was retrieved intact from the briney last weekend and the importance of a good boarding ladder so I added a second 12 mm ply reinforcing panel to give a total of 36 mm of plywood to screw into. Gluing conditions were so good that I was able to add this extra reinforcement and still install the boarding platform and have the glue cured before dark. With the afternoon sun streaming into the garage I was forced to share the pleasant working conditions with a lizard which would scurry away every time I returned. In the company of the lizard I managed to cut out panels of 12 mm ply which were then glued together to make 24 mm frames for the cradle i will need when the hull is turned.

All of the interior painting I propose to do before turning the hull is complete and I can now install the bracing across the hull to add strength for the turning process. There is still half a day of painting to do in the huge aft locker and other Jobs I can do while waiting for timber and a good weather forecast.

The high humidity is putting paid to my high hopes of turning the new yacht this month. The forecast for the rest of the week is for a lot more rain and that will not help. During the downpours I have gone shopping and stocked up on epoxy resin and paint. All the timber for the deck has been ordered but it will need dressing and sawing to size. I have bought and added three extra circuit breakers to my switch panel, bought conduit for the cable duct that will go through the refrigerator and bought the bolts needed to secure the engine mounts. In all there are sixteen bolts which will have heads under the engine so I am tack welding them to the mounting frame so that the nuts can be tightened up without getting under the engine. At least the welding can be done under cover from the rain.

I keep finding jobs that are better done now as they will be impossible later. A case in point is the ladder on the boarding platform. The ladder will have to be secured to the platform but once the platform is glued in place there would be no way to add reinforcing behind. So that means deciding on the boarding ladder to use and pre installing the reinforcing. I was reminded how important is this feature when a friend fell overboard from a yacht last weekend and was retelling the tale after sailing on Saturday. He described how hard it was to get back onto the yacht without a ladder. A little unit from Whitworths looks very sturdy and has six fastening screws and should do the job nicely.

Another job that was better done with the hull upside down was the base plate to hold the refrigerator compressor unit. It is not a big job but needed a couple of timber cleats set level. The plan is to screw the compressor to a 12 mm ply base and slide the base into position on the new cleats.

After discussion at the local club I decided to install doors on the two large bottom lockers. There is one in each of the front berth ante room and quarter berth ante room and adding doors will allow us to store heavy items low down. Today I purchased some hinges and latches so if the wet weather continues there is another job I can do.

The words of our former Twilight Captain were true again on last Wednesday when the last placed yacht in one division was awarded a prize. If Mark had not been there would we have awarded the prize to the yacht that did not finish? Yes we too won a prize courtesy of better performing yachts whose crews did not return to the club for the most enjoyable BBQ.

The race was pretty uneventful in our division except that this week Izzi got the better of us on fastest time to push us back to fifth fastest. The results do not show this but will in time be corrected and Izzi may well jump to second on handicap for the night.

The black fleet had an interesting start with one yacht starting her motor to avoid a collision and then doing turns and restarting. I agree with the principle that yachts should be able to use motors to avoid collisions but the RRS require that we specify this in our sailing instructions (rule 42.3 (i). Oh well I did say it was social sailing.

The underside of the 12 mm plywood boarding platform is saturated with three coats of West System epoxy

Only ten days to complete my job list before turning the hull! Top of the list is completing the boarding platform as this provides structural strength to the overhang from the transom. I allowed two days for this task and already it is six days but I have managed to fit in some of the other jobs. Apart from the timber work to support the boarding platform I have put epoxy fillets in the transom to hull join and in the boarding platform to hull join. Then all the new timber needed three coats of West epoxy to water proof the hull. Even the underside of the 12 mm ply boarding platform had to be coated as this area will be inaccessible after completion.

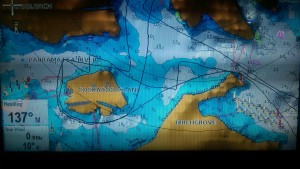

The Summer series at Greenwich Flying Squadron twilight races is a separate series that does not count towards the overall season result. Under these circumstances it is easier to be charitable to our fellow sailors when then luff above head to wind and tack on top of you on the line. Meanwhile the fleet disappears around Onion Point as we struggle to build up enough speed for the rudder to work. No one it seems bothered to take a penalty for a collision to leeward so indeed it must be social sailing. It is surprising how fast the back of the fleet can sail especially when they are on the right side of a few large wind shifts. I discovered this when we had to tack onto port at the line of moored yacht near the Woolwich marina. To avoid the following parade of starboard tackers we had to go the long way around back where we came from and away from the big lift along the Hunters Hill shore. The tracks from the chartplotter show the zig zag progress on the first leg up the Hunter Hill shore compared to the straight line on the second time around. To add to our woes for the evening we experienced a 20 degree header just as we cleared Long Nose point on the way to Goat Island.

By Goat Island we had worked up into the tail of the fleet and were just ahead of French Connection and still in contact with Farrst Company and Izzi. We did quite well on the reach and run back to Cockatoo Island and did our normal wide sweep of the wind shadow in the lee of the island. To our surprise the competitors who took the inside running kept breeze the whole way around so we hardened up at the tail of the fleet again. That was the end of the unexpected wind patterns for the evening. Our work up Humbug was efficient so that by the finish we had put Izzi, Fast Company and French Connection behind us and some order seemed to have been restored in our sailing universe. We had in the finish only a minute and a half deficit on Worlds Apart and were in turn a similar amount of time in front of Izzi. While nothing could save us from a second last on handicap the fourth fastest was some consolation considering the adversities of the evening. A lot went right on the day. I had spent a good morning working on the new build and still found time to pick up some parts for Passion and do a repair to the head. The evening on the deck at GFS was enjoyed by a large crowd in very pleasant weather and the trip back to the mooring after the raft up was in very light conditions. We were very fortunate with the weather as the conditions the following day would have made sailing and the function impossible.

In the march towards turning the hull of our Didi 40 Cr I have a long list of jobs that I would prefer to complete while the hull is still upside down. I have trimmed the excess ply form the gunwhales and double coated ply edge and gunwhale with clear epoxy. It is not the final trim but is enough to provide a smooth edge to assist the rotation of the hull when supported in slings. With the excess ply removed the hull looks more finished hence less is better.

As I have progressed with painting the interior there is less dark plywood and more white surfaces and again less dark surfaces is much better. Only the locker and the section that houses the steering quadrant have yet to be painted. These are double and triple coated with clear epoxy so the white two pack primer is more for light than for protection and at a pinch I could leave this area until after the turn.

When I have thought ahead I have masked off areas which will have cleats for the floor and deck. Elsewhere I have painted the surfaces knowing that a quick hit with the high speed angle grinder and coarse sanding pad will prepare the surface for epoxy glue.

The keel bolt holes have had their third saturation with clear epoxy. I sealed off the holes from the inside with wooden tapered plugs and filled the holes from above with epoxy. After three thorough drenchings with clear epoxy I am confident that all the end grain in the holes has been filled.

A lot has happened in the two weeks since my last post. We have had some of the family home for Christmas and then on the 27th headed up to Lake Macquarie to help out with the Australian Laser National championships. The regatta was mostly fine with light winds but the rain arrived for the last two days and the weather system developed into an east coast low after the regatta.

We brought Passion out of Lake Macquarie at the first high tide on the morning after the regatta and made a dash for the safety of our swing mooring at Woolwich in the west harbour. The trip out through the Swansea bar was fairly lumpy but the wind and wave was from straight ahead and the sea state had not yet built up to unmanageable proportions. Once through the heads we turned south, let out two thirds of the furling genoa and headed south. The winds were at the top end of the forecast range and hit 30 knots regularly at which times we made 8.1 knots over the ground. As forecast the breeze abated in the afternoon as we approached Sydney harbour and we made less speed with the full genoa and fifteen to twenty knots of wind.

Much of the trip was in rain so we left the wet genoa on the furler until today when the sun returned and the wind died allowing for a pleasant conversion of Passion back to racing mode.

Wednesday was a sad day for sailors with the loss of a crew member from Amante which was returning from the race to Coffs Harbour. Four of the yachts from Greenwich Flying Squadron sail against Amante in the RANSA winter Wednesday series so the loss of a fellow sailor hits home.

Wednesday was wet and windy even on land and at West Pennant Hills our high rainfall made the evening news. The back yard was flooded and water was flowing under the upturned hull so physical work was impossible. I took the time to order up timber for the deck of the yacht and to play around with the water system. Thursday was still too wet and humid for epoxy painting so I spend a few hours sanding and installing the water inlet pipes for the two fresh water tanks. Much of today was spent on Passion but I managed to install the two settee berth backs. These are specified as 6mm plywood but I increased it to 9mm as the box sections formed with the 6 mm shelves, the 12 mm skin and the 9 mm settee backs forms very strong anchoring for the chainplates.