Archive for September 2022

As anticlimaxes go it was as good as they get. We finished mid fleet on time and handicap and mid fleet on progress scores amongst those yachts that sailed regularly. As far as handicap racing goes that is as much as one can expect. Strategically our 1,1, 3 result in the middle of the season resulted in a significant handicap penalty from which we never recovered. Over the course of the season the handicap results were so close that a series of fourth places might have resulted in a better season outcome.

You cannot plan for these results. Once in a good place no respectable crew is going to go slow for a lower placing so it is what it is.

Not having a season victory to celebrate we will quietly slip away to some boat building and hope no one notices.

The boat building is progressing steadily if not spectacularly. A few more fine days has helped so that as of today the stern quarter of the hull is fully planked. With every plank the length gets shorter so in terms of area there is more progress.

On the wet days I have progressed some of the interior structure including the king plank hardwood doublers and the galley cupboard tracks. One key project was preparing templates of the keel base plate and keel bolts to confirm the bolt alignment before the hardwood shoe is glued to the hull. At the right moment these semi finished components will come out of the garage and get installed in what seems quick time where in fact it has been careful use of rainy days.

As for the present I have 21 more planks cut ready to install and a schedule of a minimum of 6 per day to achieve my target date for completing the second layer.

Even before the second layer is finished I am planning for the next phase which is fitting the rudder bearings and the engine shaft and P bracket. All the required parts are on order and with a bit of luck will arrive before the torture boarding and priming is finished.

After a lot of deliberation I have chosen a colour scheme for the new yacht and I hope to have the red water line painted on the hull in time for Christmas. It is the right colour for the Christmas season. Perhaps some teak and holly flooring would be in keeping with the Christmas theme.

Today I finished attaching the two layers of 3 mm ply to the bow area to form the first 6 mm layer of the radius chine. From the bow the shape of the yacht has finally taken shape and I am very pleased with the appearance. On Passion X the first two layers of 3 mm ply were placed back to back as a single double layer but for Passion X1 the two layers have been staggered. This appears to have produced a fairer first layer which i will be able to fair with the torture board before fitting the subsequent two layers.

I could not resist getting to work with the torture board to see how fairness of the bow area. The excuse I made to myself was that I needed to check the alignment before planking the port side. It seemed a reasonable rationalisation and I indulged myself with some very fine tuning of the stringers on the port side before completing the last four double planks.

It was not a busy day but rather one of careful sanding and very fine planing to ensure that the two sides would come out the same. In the process I got some exercise with the torture board and also tested the 150 mm random orbital sander.

The spotted gum timber I had ordered was ready for pick up which was a pleasant drive in the country to timber yard and also a justifation for an easy day on the tools.

With the spotted gum home and the first layer of the radius chine completed I am accumulating a long list of tasks that can be done in accord with the weather conditions. The spotted gum will go on the edges of the king plank as a very strong doubler to take the bearing pressure of the keel bolts. It will also go under the keel so I can at any time plane the “V” of the bottom of the hull and form the keel shoe.

But my priority will be to get the second layer on the radius chine so that the hull is water tight and final fairing can begin. I will need plenty of less vigerous tasks to do in parallel so it could be a good thing that the list is long.

In the RANSA winter Wednesday series there is just two races left this season. I cannot say that I am not frustrated at the windward performance compared to the Sydney 38 Agrovation and the Sydney 36Cr’s Amante and Crosshaven. To be fair they are respectivly rated 4% and 3% faster to windward and apart from sailing smarter I have to acknowledge they have the natural speed edge on the windward work.

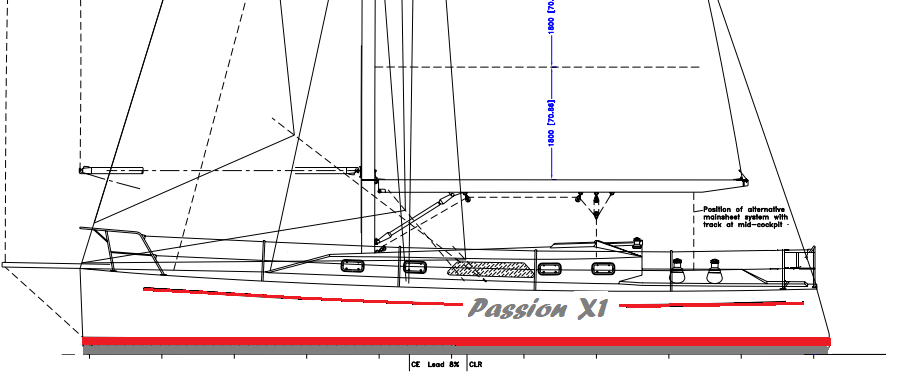

Our new yacht, the Didi 120 prototye is designed to be faster to windward and with a longer waterline still have good downwind speed but it will be winter 2024 before we can put it to the test.

When we finish in front of Allegro and Joli and alongside Foreigh Affairs we expect better than ninth place so I was disappointed when the results came out. We had our best sails for the conditions but from the start Amante and Crosshaven took off and were never headed. Agrovation with a smaller than expected headsail managed third over the line due to their good upwind speed but their handicap put them one behind Passion X.

I mention we finished near Foreign Affairs so their last place on handicap was no suprise but what was suprising is that they did not get away.

Perhaps the Sydney 36CRs have a special trick up their sleeves in such conditions and full marks to Crosshaven for a good win. Also full marks to Monkey Magic for second place but almost three minutes behind Crosshaven. If Crosshaven was an athlete she would be asked to pee into a bottle.

That’s enough about the race now what has been going on at the boatyard?

To be fair a lot of other activities have been going on. We have over the last few week demolished 15 metres of fence and sent that to the tip in a skip bin. Next we demolished a large garden shed and sent that to the tip is a similarly large skip bin. Then there was repairs to a trellis that had been demolished by the tree fellers when they removed the large gum from the back yard. All has not yet returned to normal as the contents of the garden shed that we wish to keep are spread around the property awaiting a new one.

Against this backdrop I have been plodding along on the radius chine planking.

There was a brief interruption to get the four coats of epoxy paint into the water tanks before the planking obstructed the access and the fairing of the radius chine doublers has had to be kept going in advance.

The radius chine is fixed to a 100 mm wide 12 mm ply strip which is attached to a 32 by 22 stringer. The flat panels attach to 50 mm of the strip and the radius section attaches to the other 50 mm. Before attaching the radius section the 50 mm strip has to be planed to the curve and in the planing process the longitudinal shape has to be maintained. At the rear the curve is so large that the fairing is quite simple but as the work approches the bow the curve is much sharper and the amount of ply to be planed off is more.

At the bow for the first 5 metres I had not routered the step in the 12 mm ply as it was going to be out in the weather for a while and I wanted to leave the 6 mm step until I was ready to do the curve. That time arrive today.

I had been a bit anxious about the routering on the upturned hull but by carefully fastening a long timber batten to the hull as a guide the process went rather well.

The rest of the day was spent fairing the 50 mm of ply to the radius shape and apart from a final fiddle just before gluing it is finished.

Now I have few excuses left for plodding progress. There is nothing stopping me completing the front half of the first 6 mm ply layer and moving on to the second layer. So it is 40 done and 120 to go.