Archive for November 2022

I have been busy. Last weekend was the Laser state titles at Wangi Wangi which kept us occupied for two days and away from boatbuilding. A rest from boatbuilding was needed as the overuse injuries are starting to mount up and I am having to pace myself with the manual labour. Still a lot has happened and so this will be a catch up blog.

First the yacht racing where we scored a third and a first place in the last two Wednesday events. The first place was last week when we were given second on the night but the winner must have overlooked his crew list. No big deal as we all move up one point and the series stays in the same order. It was one of those nights where if you get out of Humbug early you establish a good lead and that is what we did. It is a rare race indeed when we beat the Sydney 38 Utopia by quite a few minutes. Congrats to Adrian for fastest time and commiserations to Steve who was second fastest on the night.

On the boat building scene I spent the Thursday and Friday prior to the Laser regatta trimming the excess plywood from the gunwales. This is an awkard job as the angle is uphill so by the end of two four hour sessions my arms were pretty tired but I am very pleased with the result.

My engine beds were delivered saving me a long trip and after a few trial fits and epoxy coating or the timber base the metal angles are firmly bolted in their final position.

One of the achievements of the past fortnight was to manufacture an epoxy glass stern tube which is twice the thickness of the off the shelf items. I had an ideal mandrel in the form of 32 mm OD fibreglass pultrusions with a highly polished surface. I did have to use the one tonne chain block to extract the mandrel but the result is very pleasing.

On Thursday I collected my drive train components and on Friday and promptly bedded in the P bracket and stern tube using the bearings dry fitted as alignment guides.

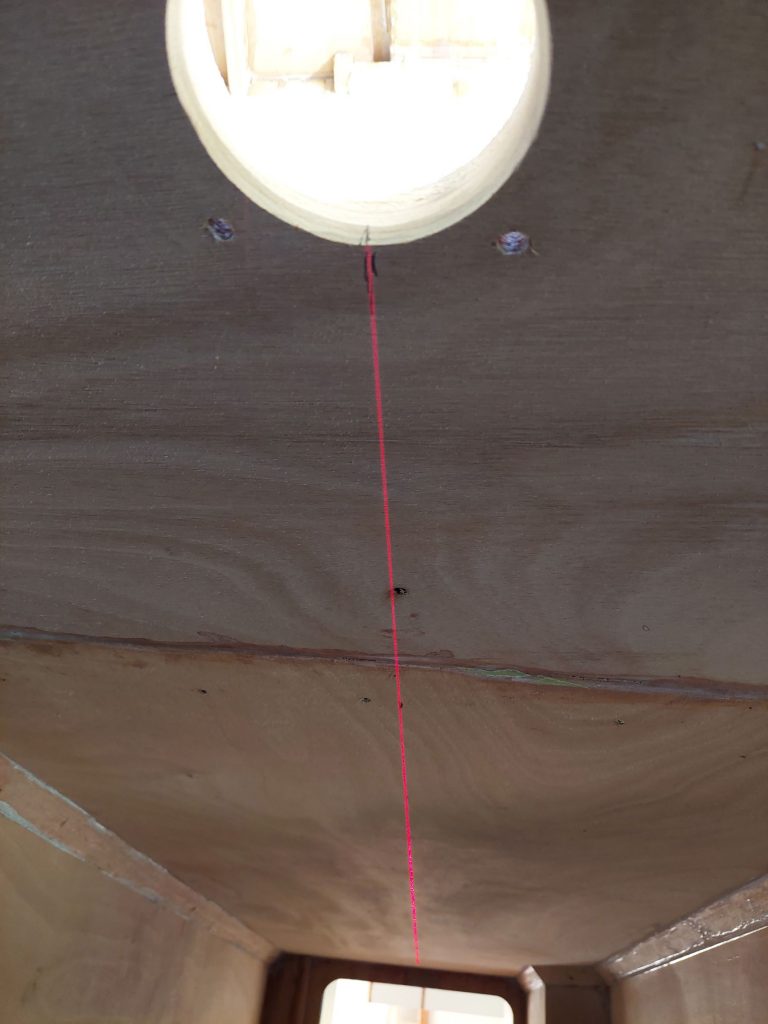

On Friday I cut out the holes for the rudder stock having previously reinforced the hull with 24 mm of plywood attached to the 12 mm skin and fixed between the strongback and the stringers. The cutting was accomplished with the required diameter hole saws in very quick time. A post cutting alignment check was conducted mainly to get the tiller stop on the upper housing exactly on the centre line.

The lower bearing housing has been fabricated and after a couple of days the mandrel will be pressed out of the moulding leaving me ready to fix the rudder stock position.

It was great to see the big Ausreo out on Wednesday night even if they did disappoint us by powering past on the final work to the finish. Weather wise it was the best of the season and that no doubt brought out the big Beneteau and hopefully they will keep up the appearances.

We were down on crew numbers for the night and that meant we were not the quickest tackers in the fleet so our handicap results suffered. Another minute and we would have been mid fleet so it was not a disaster and everyone gets a turn with the handicap system.

On fastest times we were a long way behind Jackpot who took off out of Humbug and was never troubled. Fully powered up she is a fast ship and quite a contrast to the reefed mainsail result from last week.

Joli had another good race and seemed to like the conditions but even given she sailed well the gap back to Passion X was excessive. From the results it was clear that the earlier starting fleets had relatively better times around the course than the later ones and the slower of the later ones seemed to have been left out on the course.

We did not do well on the run back from Goat Island and could see the slower yachts from behind rapidly closing the gap with freshing breeze and the bigger Blue fleet yachts did blanket us for much of the run. It was not until we turned the corner at Cockatoo for the work home that we got clear air and streatched out from the Blue Fleet.

It was at this stage that Ausreo went through our lee like we were standing still and perhaps we were. Perhaps we were staying too close to Cockatoo to avoid the Blue fleet running over the top and while we did that Ausreo left us in their wake.

On the boat building front I moved from the bow to the stern and added the final layer of 12 mm ply to the rear edge of the boarding platform. This forms a formidable box section comprising two layers of 12 mm ply on the two faces and a layer on the top and bottom edge all stiffened with webs and stringers. While the bow is massive with four layers of 32 mm meranti on top of 36 mm of ply the stern is equally strong.

These last two jobs left me with a seriously sore shoulder and an inclination for lighter duties which included fitting the external keel shoe, doing the external glass on one of the ply joins, cutting the hole for the stern tube and locating the P bracket. These were all tasks requiring more care and attention to detail than the robust planing of the bow and are jobs that are due to be done.

Today I attempted to manufacture the stern tube out of epoxy glass. While I say attempted I mean it is made but it is stuck with less than half off the mandrel. Tomorrow I will jury rig the 2 tonne chain block to see if they can be parted of if I have to start again when fresh supplies of fibreglass arrive.

Wednesday was a challenge both for the officials and the contestants. The breeze had been above the forecast all day but was due to subside around start time. As it had backed off a little the race started on longish courses as befits a windy night and we all finished in the light.

With our tiny crew of four with two on light duties it was a challenge but we managed well due to the heroic efforts of Kevin who was treating it as a Laser race.

Elaine and Frank did great jobs grinding in the No 3 jib despite the windy conditions. I did promise Frank that I would but larger winches on the next boat and we will definately go up a size to 50’s.

For the night we swapped the mainsheet to the port side so that the No1 reef line could be kept on the starboard winch and that worked well in keeping the foot flat.

Most of the fleet sailed with a reef although Utopia did not and Joli took her reef out in the pre start. This I had not noticed but once in Humbug Joli took off. This was a good thing and a bad thing as leading the fleet Joli sailed the White board course and left the rest of us to sail all the way to Spectacle Island.

It was a quick trip to Spectacle, Snapper and back to Goat where we passed the Blue Fleet which means we did the extra miles in 5 minutes.

Out in front of the Blue Fleet was Hula pretending to be a Farr 40 or something. To be fair we did pass her around Goat but once on the work home she took off showing her Black Fleet capabilities. I do like to tease DJ about that.

We went wide around Goat Island and were still in the hunt with Jackpot and Meridian at the red bouy but on the way home we were not as nimble with the tacking on the shifts.

Irukandji was more nimble and passed us up the work to Cockatoo but we almost caught her once on the free leg back to Humbug.

Unlike last weeks purgatory, Humbug was more foregiving and apart from letting the big Hanse 400 run over us no damage was done and there was no last minute recovery for Sweet Chariot.

At the finish we managed a second on handicap which was very pleasing for such a small crew.

Back at the building site progress has been very measured as I have been battling a persistent ear infection and the antibiotics are knocking me about. While working at a more measured pace I have made a lot of progress but no torture boarding. Notable jobs have been finishing the king plank doubers inside the hull and making the keel shoe out of spotted gum to go between the plywood skin and the steel fin. I have yet to shape the side of the keel shoe that goes against the hull as the shape forms a curve in profile as it intersects the V of the bottom. It is ready to be shaped in profile and there are new sharp blades in the Makita. They will be needed as the timber is very hard indeed.

Today I shaped the last of four layers of 32 mm meranti that form the bow. From by stockpile I selected some medium density for the first two layers up agains the 36 mm of plywood at station 0 and some very dense merati for the front two layers which will take the bolts for the forestay fitting. The hard timber was hard going and as I glued and faired each of the four layers individually it was a four day job.

The glue in the last layer cured overnight so today I changed the blades in the Makita and spent four hours planing by machine and by hand and sanding by machine and by hand until I could do no more.

As an escape from the hard work of hand planing I have been working on the companionway steps. This all started because as I was selecting timber for the bow I spotted a length that was pretty tough but straight grained and thought that would make a good set of steps. And so it is that they are made in plenty of time for epoxy coating and varnishing before they are put into use when the hull is turned.