A wild front just went through with wind gusts over 50 knot so it was a good time to pause and do a progress report.

At the time of the last report the lower rudder stock bearing had been laminated and was curing. The following day I trimmed off the rough edges of the upper flange and lower rim before the resin went rock hard. The following day I had planned to remove the mandrel thinking it would be a major exercise but to my surprise the mandrel literally fell out of the housing. I attribute this to the fact that the laminating was done on a hot afternoon with the mandrel expanded with the heat and in the cool of the morning the clearance created was enough for it to slip out without any assistance.

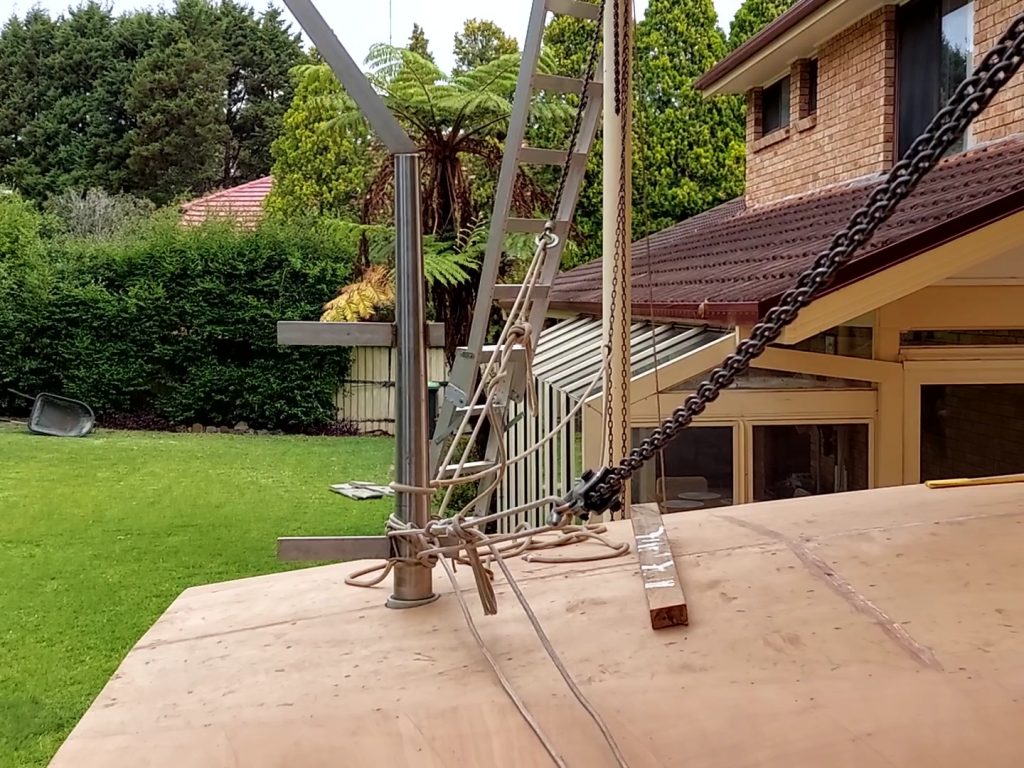

The next job was to get the rudder stock into position so that the upper and lower bearings could be aligned. That was easier said than done as the weight of the stock exceeds my lifting limit. With the aid of two chain blocks suspended from the awning I managed to get it into position and do the alignment late at night when the lines from the laser level were easily seen.

That meant a late finish as the gluing of the bearing housing into the strongback had to happen later that evening.

Once the glue had cured it was time to add the reinforcements to the housing and as that meant working the laminates upside down I proceeded with caution with first the stern gusset bonded into the transom gusset and glass wrapped around the bearing housing. Next day I glued in place the 12 mm plywood transverse gusssets and the forward one and once that glue was cured I could start the laminating. Again proceeding with caution I did that in three stages until all three 12 mm ply gussets had six layers of 420 gsm double bias glass around them.

On Friday we had an early Christmas get together with some of the family and my two eldest boys lifted the rudder stock out of the bearing housings and helped me get it to the garage for storage. That was a bonus task completed in short time.

In between laminating in gussets I have been progressing the hull fairing along the radius chine and have started glassing the centreline join. I cannot do long periods of torture boarding so I am fitting in less physically demanding interior tasks.

Today with the wind and rain I had a reprieve from the hard work but managed to fit some of ply doublers over the stringer notches. At this stage they are all cut and I am down to the last two frames for gluing.

For the record we did win the spring series on handicap from Utopia. Before the race John said it was time for us to win a seried but then then put on a master display and won the race. We held on by a single point but a win is a win.